Johnson Plastsonic manufactures various types of sealing machines for fabric and films.

Pleated filter sealing machines, bag type filter sealing machines are manufactured as per requirement.

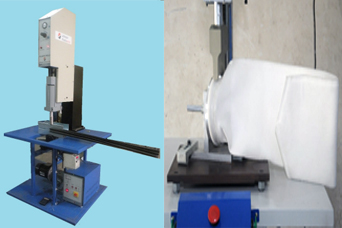

Plated Filter / Velcro Sealing Machines Manufacturer, Supplier, Exporter

Johnson Plastosonic is the Manufacturer, Supplier, and Exporter of Plated Filter Sealing Machines and Plated Velcro Sealing Machines. Our setup is located in Pune, Maharashtra, India.

We manufacture various types of sealing machines for fabric and films, including pleated filter sealing machines and bag-type filter sealing machines, tailored as per customer requirements.

A Plated Filter/Velcro Sealing Machine is a specialized industrial tool designed for sealing or attaching components, particularly filters or Velcro fasteners.

These machines are used in industries like automotive, HVAC, or water purification to seal or assemble filters. Key features include:

- Plating Functionality: Involves metal or protective coating layers for durability.

- Sealing Mechanism: May use heat, adhesives, or ultrasonic sealing.

- Applications: Used in the production of air filters, oil filters, or industrial filtration systems.

- Automation: Often equipped with automation for high-speed manufacturing.

These machines are used to attach Velcro strips to various materials, typically in the textile or packaging industries. Key features include:

- Heat or Ultrasonic Bonding: Commonly used for strong adhesion.

- Customizable Lengths: Allows for different sizes of Velcro strips.

- Precision Alignment: Ensures accurate placement of Velcro.

- Enhanced Sealing Efficiency: These machines ensure a tight and consistent seal, reducing the risk of leaks or failures in products like air filters, liquid filters, and Velcro fasteners. The plated filter and Velcro components are aligned accurately for maximum effectiveness.

- Versatility: Can handle various materials like textiles, plastics, foams, and composite materials. Can be tailored to meet specific product dimensions or design requirements.

- Cost Efficiency: High precision in sealing minimizes material wastage. Durable construction and reliable operation result in fewer breakdowns and lower maintenance expenses.

- High Productivity: Automated operations allow for quicker sealing processes, leading to higher production rates. Suitable for both small-scale and large-scale production runs.

- Improved Product Quality: Eliminates variability in manual sealing, ensuring consistent quality in every unit. Creates seals that are resistant to environmental stressors like heat, moisture, and vibrations.

- User-Friendly Operations: Many machines feature intuitive controls and minimal setup requirements. Modern designs include safety mechanisms to protect operators during operation.

- Compliance with Standards: Ensures that seals meet regulatory and performance requirements, particularly in critical industries like automotive and healthcare.

- Environmentally Friendly: Advanced models consume less energy compared to traditional methods. Compatible with eco-friendly materials, promoting sustainable manufacturing practices.

Plated Filter / Velcro Sealing Machines are widely used in various industries for sealing, laminating, or attaching Velcro and similar materials. These machines offer precision, durability, and efficiency across multiple sectors, enhancing product quality and reducing production time.

- Automotive Industry

- Filtration Systems

- Textiles and Garments

- Packaging

- Aerospace and Defense

- Medical Devices

- Electronics

- Furniture and Upholstery