We are the Manufacturer, Supplier, and Exporter of Ultrasonic Manual Bag Sealing Machines. Our setup is situated in Pune, Maharashtra, India.

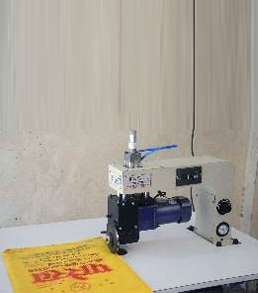

Ultrasonic Manual Bag Sealing Machines

An Ultrasonic Manual Bag Sealing Machine is a device designed for sealing plastic or thermoplastic bags using ultrasonic technology. This type of machine is often used in industries such as food packaging, pharmaceuticals, chemicals, and electronics, as it provides a clean, strong, and airtight seal without requiring heat or adhesives.

The machine generates high-frequency ultrasonic waves (typically 20–40 kHz) using a transducer. The ultrasonic energy is directed to the sealing area of the bag through a specially designed horn or sonotrode. The ultrasonic vibrations generate localized heat due to friction, melting the plastic layers at the interface. As the material cools, it creates a strong and seamless bond.

- Precision Sealing: Suitable for delicate materials or intricate packaging needs.

- Manual Operation: Allows flexibility and control in small-scale or custom packaging applications.

- Heat-Free Process: Does not require direct heat, reducing risks of burns or material damage.

- Compact Design: Lightweight and portable, ideal for small businesses or on-site sealing needs.

- Environmentally Friendly: Does not require adhesives or consumables like tapes or glues.

- Strong and Clean Seals: Produces airtight, strong seals that are resistant to leaks.

- Quick Sealing Process: Faster sealing process compared to traditional heat sealers.

- Material Compatibility: Compatible with a wide range of materials, including polypropylene (PP), polyethylene (PE), and multilayer films.

- Food Packaging: Sealing snack bags, vacuum-sealed products, and resealable pouches.

- Medical and Pharmaceutical: Ensuring contamination-free seals for sterile products.

- Industrial Use: Sealing chemical bags or protective packaging.

- Electronics: Securing components in anti-static bags.

Ultrasonic sewing machine USM1 comes rotary pattern roller and rotating horn. Pneumatic based system with stepper motor and control. Easy operating foot switches.

SPECIFICATIONS

Size |

L*W*H =43"26"*50" |

Weight |

95 KG |

Table plate operating size |

L:390mm W:300mm fixture parallelism adjustment provision. |

Operating height |

750mm |

Distance |

Throat depth:11" |

Color |

Blue 5010 AND Siemens gray:7035 |

Pneumatic |

Make SMC Japan Cylinder: Bore 2" Stroke length:2" |

Drive system |

Stepper motor: Torque 60kg and 60 kg each, digital drive micro stepping adjustment With pulling roller system of Aluminum roller and rubberized roller combo for excellent fabric grip |

Coarse up down |

Pneumatic |

Generator |

UG 2010 (20Khz 1000w) |

Input suppy |

230v AC 1Phase |

Start |

Foot operated switch operation |

Roller |

Hardened tool steel roller grinded with pattern |

- USWM: Ultrasonic spot welding machines

- Ultrasonic face mask Tie spot welder

- Ultrasonic surgical gown tie spot welder

- Ultrasonic hand held welding guns

- Ultrasonic sewing machines

- Ultrasonic spot welders

- Ultrasonic liquid processors

OTHER MODEL AVAILABLE

USM2 : Ultrasonic sewing machineOther machines available