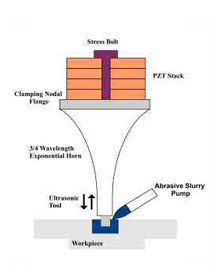

Ultrasonic milling is a relatively new process that allows efficient machining of so-called advanced materials such as hardened steels, carbides, glasses and ceramics. With the aid of an ultrasonic spindle, the vibration of the machine is transferred to a diamond tool, The tool vibrates at a rate of 20, ooo times per second and thus remove minuscule particles from the surface of the workpiece. The simultaneous circular motion of the tool removes these particles from the working zone. In addition, the continuous separation between tool and workpiece, in conjunction with the reduced feed power and lower thermal stress in comparison to conventional methods, leads to protection of tool and workpiece, Machining is carried out much like conventional milling. Ultrasonic milling makes it possible to machine finished parts in very hard materials at a considerably faster rate than other methods such as Dimon cutting tools or gringing. 2 to 50 microns vibrations are given which can be adjusted electronically. Machining is done with minimized mechanical & thermal damage.

Cutting forces are reduced by 75% All brittle materials glass, technical ceramics, ferrite quartz, tungsten carbide, sapphire, ruby and even diamond can be abrated in the way.